Students at Michigan Technological University’s Copper Country Robotics Team (CCRT) have designed and built a functional robot in just 72 hours as part of the Robot in 3 Days (Ri3D) challenge.

The challenge started at noon on Saturday. CCRT members worked non-stop over three days to prototype a robot performing tasks similar to those assigned to high school teams, who have six weeks to build their machines.

The build took place in the Alley Makerspace, a collaborative facility located in Michigan Tech’s Memorial Union Building. The space provides access to tools for electronics, 3D printing, machining, and woodworking, enabling rapid prototyping under tight time constraints.

Also Read: Teen Builds Fully Functional Robotic Hand from LEGO Parts

According to MTU computer science major David Reeves, this was the second year CCRT has taken part in the Ri3D challenge, with participation increasing compared to the previous year. Around 40 students registered, with team members contributing across a range of different tasks throughout the build.

Rather than working in isolation, students shifted between responsibilities as the robot took shape, adapting to design changes and technical constraints as they emerged over the three-day window.

Jocelyn Shaffer, a mechanical engineer on the team, emphasized the importance of coordination under the tight schedule. “You have to have constant contact between the design team and prototype in the beginning and now,” she said. “You check in with other teams, and as soon as you have to go ahead, you can work on the next thing.” Even small delays or miscommunications could ripple through the build, underscoring the critical importance of team coordination throughout the process.

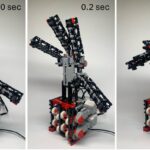

By noon on Tuesday, CCRT had completed a fully operational robot. The robot uses a front-mounted roller mechanism to collect six-inch yellow foam balls from the floor. The balls are then carried through an internal hopper and shot into a target hub using a flywheel shooter.

While the robot was operational, some secondary components remained incomplete due to hardware shortages and time constraints. “We got a couple of things I think we’re going to have to push off, such as we have bumpers that we still have to create, just due to a lack of hardware Monday night,” Reeves said. “Then, some LED issues, which, without time for the robot, we’re not really able to solve.”

Also Read: Scientists Create Robotic Rabbits to Fight Invasive Burmese Pythons in Florida

Working under those constraints is a deliberate part of the Ri3D format. The limited build time forces teams to prioritize essential systems first, often leaving non-critical features for later refinement once the core mechanisms are proven. The process encourages participants to coordinate quickly, make informed engineering trade-offs, and demonstrate practical problem-solving skills under real-world time pressure.

For the Michigan Tech team, the focus of Ri3D was collaboration rather than competition. “We try to collaborate. We bump ideas off of other teams. We watch other teams throughout this process,” said Reeves. Teams from different institutions shared design ideas and troubleshooting approaches, which are often followed by high school robotics teams looking for early-season inspiration.